What are the benefits of woodworking CAD/CAM software? Mastercam’s woodworking solutions were used to produce the waterwheel exhibit at the American Precision Museum in Windsor, Vermont. Regardless of the CNC’s application, productivity is essential to growing any business. Its applications are only limited by the creativity of its users, and the production of almost any piece can be improved with CNC woodworking. For the complex and incredibly precise inner components of a clock, operators can use CNC mills. For intricate banisters, operators can turn to CNC lathes. For attractive, eye-catching signs, operators can rely on CNC routers to carve out text and images. What are common applications for CNC woodworking?Īny production shop can benefit from the incorporation of CNC, regardless of what its specialty might be. CNC woodworking can add an element of precision and efficiency that offers just that profitability, especially when paired with CAD/CAM software.

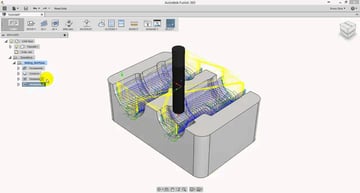

Luckily, many shops are starting to appreciate the value of CNC (computer numerical control). When the economy stumbles and material prices soar, like during the pandemic, a woodworking company’s approach to this dilemma can mean either its demise or success. Meeting both expectations-aesthetics and utility-often poses a problem for woodworking shops, and it can even cut into revenue. Woodworking customers expect a certain standard of beauty on top of a product’s function. The Mars Society Rover Challenge SeriesĬompared to the traditional manufacturing industry, the woodworking industry is much more well known for the charm and aesthetics of its parts.Robotics Education & Competition Foundation (REC).Thanks to this, the iterations of CNC programming become less time consuming, and comparing to other CAD/CAM software the CNC programming workflow itself becomes intuitive and clear. Using the result, the user can easily decide how to correct the parameters without switching to simulation or postprocessing. Immediately after the toolpath is calculated, SprutCAM performs the simulation in the background and shows the new state of the workpiece to the user in the same window. This means that the CNC machine is 100% able to execute the generated program. The result of the calculation is not just the Cartesian points in abstract space it’s the actual positions of the machine axes required to reach these points. Kinematics and rest material consideration on every stepĪll the limitations of the machine model kinematics and the actual rest material that remains after previous operations and the fixture(s) geometry are used to calculate the toolpath.

After that it’s easy to estimate the reachability of the surfaces when picking them for the machining. Before starting the programming, the user puts the models of the part and fixtures inside the virtual machine. SprutCAM is a CAD/CAM software that takes into account the CNC machine model during the toolpath calculation.

0 kommentar(er)

0 kommentar(er)